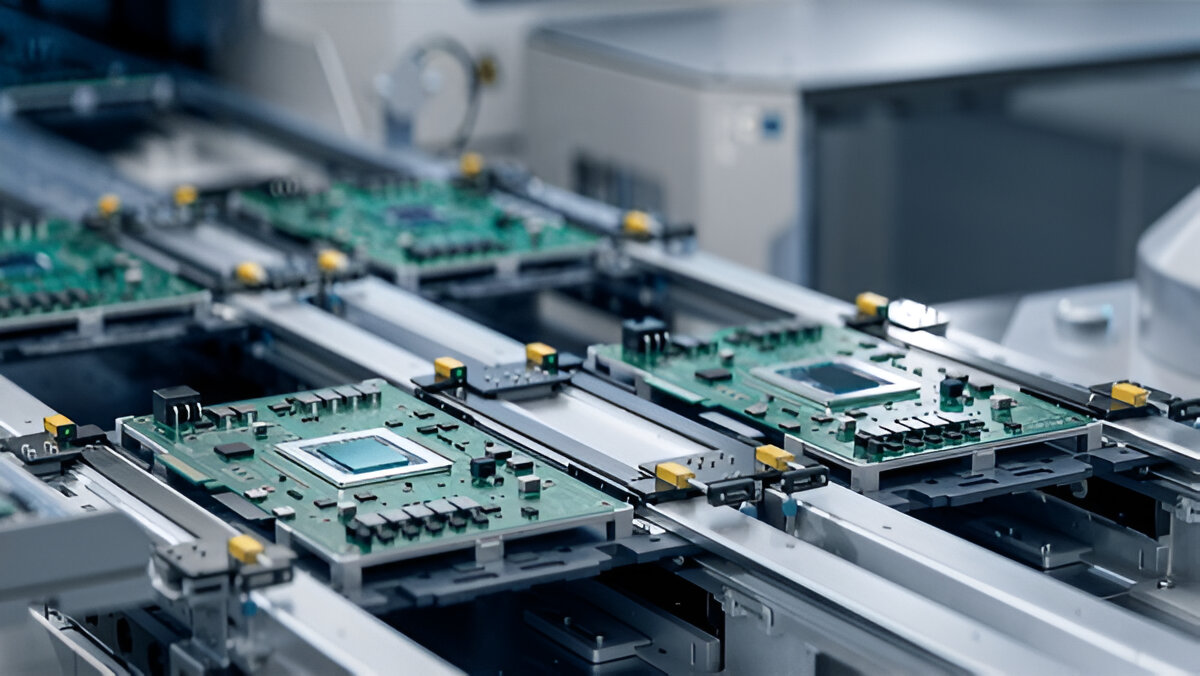

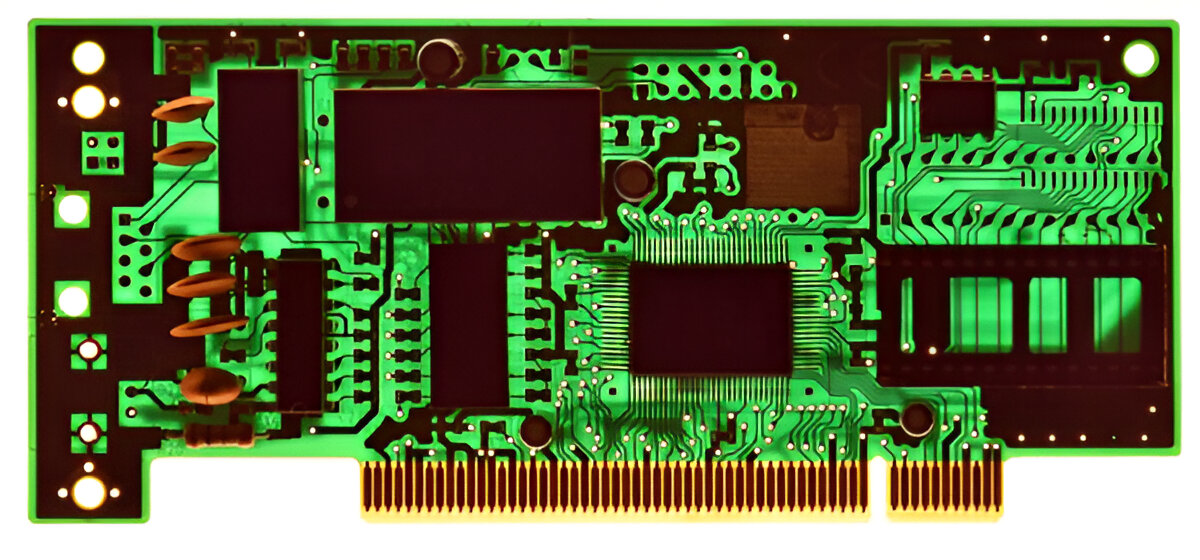

In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) assembly has revolutionized how components are mounted on printed circuit boards (PCBs). Unlike the traditional through-hole method, SMT allows for higher component density, resulting in smaller, more efficient designs and faster production times. This advancement is crucial for electronics assembly in industries demanding compact and high-performance products.

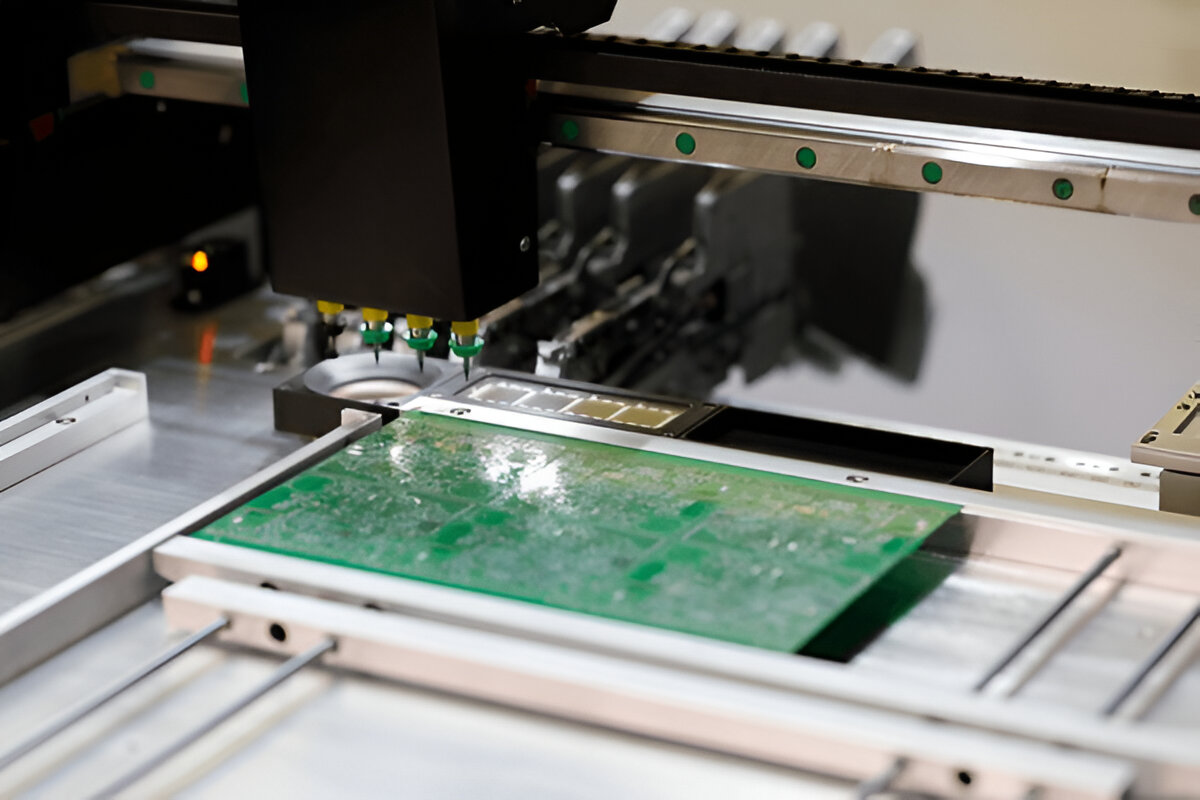

SMT components are smaller, lighter, and more reliable, making them ideal for automated industrial PCB assembly lines. The process starts with precise solder paste application, followed by the placement of components using advanced pick-and-place machines that operate with millimeter precision. Once placed, the PCBs go through a reflow soldering process where heat melts the solder, securing the components firmly in place.

At Aear, we take pride in delivering top-tier industrial PCB assembly services. Our commitment to quality begins with the latest industry practices and state-of-the-art equipment. We meticulously manage the soldering process to ensure precision in component placement and the integrity of solder joints. Each PCB undergoes thorough inspection using automated optical inspection (AOI) systems and rigorous testing to detect and correct any defects. This ensures that every assembled PCB is not only high-performing but also reliable and durable. For high-quality electronics assembly and industrial PCB assembly that meets your needs, trust Aear's expertise in Surface Mount Technology (SMT) assembly.

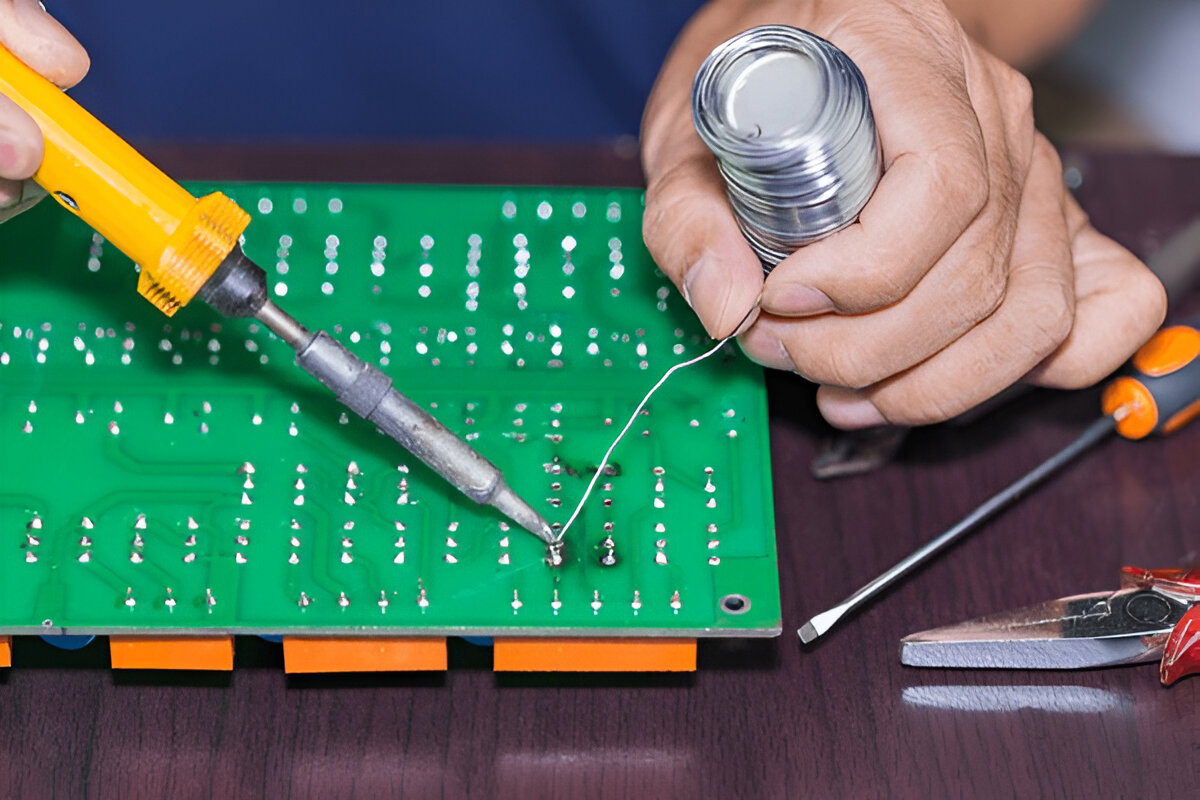

Through-Hole Technology (THT) assembly is a widely used method for attaching electronic components to printed circuit boards (PCBs). In this process, leads of components are inserted through holes drilled in the PCB and then soldered to pads on the opposite side of the board. THT is ideal for applications that require robust, durable connections, making it perfect for components that experience mechanical stress, such as connectors, heavy-duty components, or power components. The process begins with the insertion of components into the board’s holes, followed by wave soldering or hand soldering to ensure strong, reliable connections. The versatility of THT assembly makes it suitable for a wide range of industries, including automotive, aerospace, and industrial electronics. While SMT (Surface Mount Technology) has grown in popularity, THT remains crucial for applications requiring high mechanical strength and durability.

Aear ensures top-tier quality in its Through-Hole Technology assembly by employing advanced soldering techniques and strict quality controls. Our team uses automated systems to ensure precise component placement and robust solder joints. After the assembly process, thorough inspections, including Automated Optical Inspection (AOI) and X-ray analysis, ensure no defects are present. This guarantees that every PCB we produce is reliable, durable, and meets the highest industry standards.

At Aear, we excel in Through-Hole Technology assembly by leveraging advanced machinery and expert craftsmanship. From the careful component insertion to precise soldering, we ensure that every step meets the highest standards. Our stringent quality control processes guarantee the most durable and reliable connections for all your PCB needs. Trust Aear to provide you with top-quality THT assembly for even the most demanding applications.

Mixed Technology Assembly combines both Surface Mount Technology (SMT) and Through-Hole Technology (THT) in one single PCB design. This hybrid approach allows manufacturers to utilize the best features of both technologies, offering greater flexibility in component selection and design complexity. SMT is ideal for compact, lightweight components that fit directly on the surface of the PCB, while THT is used for heavier or more mechanically demanding components that require stronger physical connections. This technique is widely used in industries like automotive, telecommunications, and aerospace, where performance, durability, and high-reliability are critical. The assembly process involves careful placement of both surface-mount and through-hole components, followed by soldering, typically using wave soldering for THT components and reflow soldering for SMT components. With the integration of these two methods, companies can optimize for both performance and cost-efficiency, ensuring robust functionality in diverse applications.

Aear is committed to ensuring the highest quality in its Mixed Technology Assembly by employing the latest automated systems for precise placement and soldering. Our quality control team performs rigorous inspections using state-of-the-art AOI systems and X-ray inspections to guarantee that every PCB meets the highest standards for durability and functionality. This combined approach allows Aear to deliver products that offer superior performance while maintaining cost-effectiveness.

At Aear, we specialize in Mixed Technology Assembly, combining the best of SMT and THT for efficient, high-performance PCBs. Our advanced systems ensure precise placement and quality control, delivering a robust final product that meets rigorous industry standards. Whether you need complex designs or durable, high-reliability applications, trust Aear to provide expert assembly solutions tailored to your requirements.

BGA (Ball Grid Array) and Micro-BGA (Micro Ball Grid Array) Assembly are advanced PCB assembly technologies used for high-density, high-performance applications. BGA technology allows for greater I/O (input/output) capacity with reduced board space requirements. BGA components are soldered directly to the PCB using solder balls placed under the component, which improves electrical performance and minimizes the risk of signal interference. Micro-BGA, a smaller variant, is used in applications where space is extremely limited, such as mobile devices, medical equipment, and high-speed electronics. The assembly process for BGA and Micro-BGA involves precise component placement, often through automated pick-and-place machines, followed by reflow soldering. Post-soldering inspection, such as X-ray imaging, ensures that the solder joints are free of defects, which is critical for maintaining the integrity of the high-speed signal transmission and overall functionality of the assembly.

Aear's expertise in BGA and Micro-BGA Assembly is reflected in the use of precision equipment and stringent quality control measures. Our dedicated team ensures every BGA component is securely placed and soldered with exceptional accuracy, reducing the risk of solder defects and enhancing overall board reliability. Aear leverages cutting-edge techniques like X-ray inspection and Automated Optical Inspection (AOI) to verify the integrity of the solder joints and ensure the highest possible quality. By implementing these methods, Aear delivers products that meet the most demanding standards in terms of performance, durability, and long-term reliability.

Aear offers specialized BGA and Micro-BGA Assembly services that ensure high-density and reliable electronic solutions. Our expert team guarantees precise assembly, quality assurance through X-ray and AOI systems, and rigorous attention to detail in every project. Whether you need compact, high-performance assemblies for consumer electronics or other specialized applications, Aear provides expert solutions tailored to meet your specific requirements.

Lead-free soldering, as defined by the RoHS (Restriction of Hazardous Substances) directive, plays a pivotal role in environmentally responsible electronics production. The process uses solder alloys that do not contain lead, typically based on combinations of tin, silver, and copper (SAC). These lead-free alloys offer excellent thermal and mechanical properties, making them ideal for modern electronic devices. The soldering process involves heating these alloys during the reflow process, ensuring that the connections between components are strong, durable, and reliable. By adopting this method, manufacturers not only comply with global environmental regulations but also enhance the overall performance and longevity of their products. Industries such as consumer electronics, automotive, and medical devices rely on RoHS-compliant lead-free soldering to ensure their products are both safe and durable. At Aear, we use the latest technology and quality assurance measures to deliver exceptional lead-free soldering that adheres to the highest standards.

Aear guarantees top-quality lead-free soldering by employing advanced reflow soldering techniques, precise temperature control, and using the best RoHS-compliant materials. Our highly trained engineers ensure that all solder joints are secure and reliable through extensive post-soldering inspections. By focusing on process consistency, defect minimization, and the long-term durability of the solder joints, we ensure that every product meets and exceeds industry standards. Our dedication to quality and environmental responsibility sets Aear apart as a trusted partner in lead-free soldering solutions.

With Aear, expect the highest standard in RoHS-compliant lead-free soldering. Our experienced team provides safe, durable solutions for all your electronic assemblies, ensuring maximum performance and reliability.

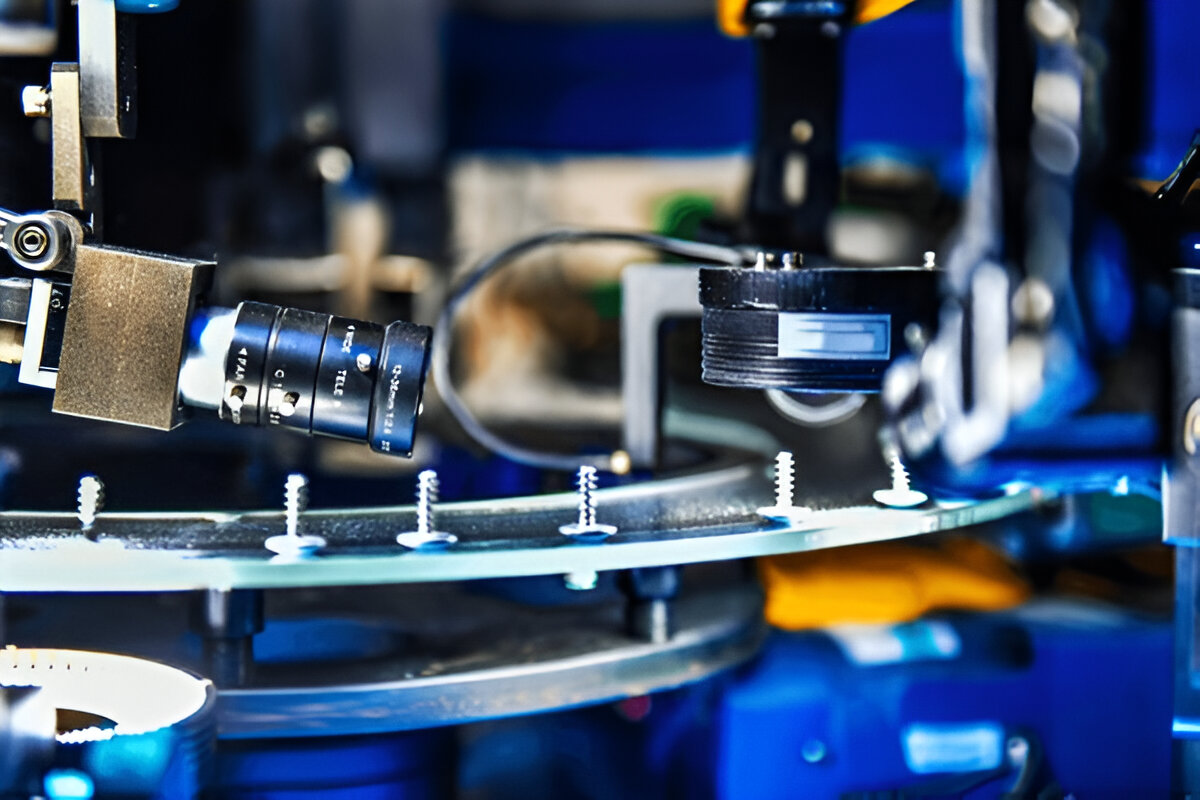

Automated Optical Inspection (AOI) is a critical process used in PCB manufacturing to ensure the highest levels of accuracy and quality. It employs high-resolution cameras and sophisticated software to inspect solder joints, component placement, and other essential elements on a PCB. The AOI system scans the PCB after assembly, comparing the actual layout to the intended design, identifying defects such as missing components, misalignment, and soldering issues. This technology reduces human error, enhances precision, and accelerates the inspection process. By automating the quality control checks, AOI helps to guarantee that the final product meets the strictest standards for functionality and reliability. The use of AOI is particularly important in industries where product failure can have serious consequences, such as automotive, aerospace, and medical devices. Aear employs state-of-the-art AOI systems to ensure that all PCBs pass through rigorous quality control before reaching our clients.

At Aear, we integrate the latest AOI technology to guarantee the highest accuracy in identifying defects, offering a reliable way to detect both visible and hidden problems. Our systems are programmed to detect even the smallest anomalies, ensuring that your PCB performs flawlessly. This attention to detail and commitment to quality control ensures that every product leaving our facility meets stringent standards, providing peace of mind to our clients.

Aear's AOI systems deliver precise, automated inspections, ensuring your PCB assembly meets industry standards. Trust us for efficient, high-quality inspection results.

X-Ray Inspection (XRI) is a crucial method for non-destructive testing in the PCB assembly process. It uses high-energy X-rays to peer inside the PCB, allowing for an accurate inspection of solder joints, BGA (Ball Grid Array) components, and other hidden features that are not visible through traditional methods. This inspection technology enables manufacturers to identify issues like insufficient soldering, voids in the solder joints, component misalignment, and even internal cracks or defects. X-Ray inspection is especially beneficial for complex PCB designs, where components are densely packed, making visual inspection difficult or impossible. It ensures that every solder connection and component integrity is up to standard, which is essential in high-reliability applications like automotive, aerospace, and medical devices. Aear utilizes advanced X-ray systems to provide thorough and accurate inspection results, guaranteeing the highest level of product reliability and performance.

Aear’s commitment to using the most advanced X-Ray technology ensures that no defect goes unnoticed, even in the most intricate PCB designs. Our X-ray systems allow for detailed, precise analysis of both external and internal features, including hidden solder joints and internal board structures. This attention to detail ensures that our products are defect-free, offering long-term reliability and performance in demanding applications.

Aear's advanced X-Ray inspection guarantees detailed, defect-free PCBs for the highest-quality, reliable performance. Trust us for accurate, non-invasive inspection solutions.

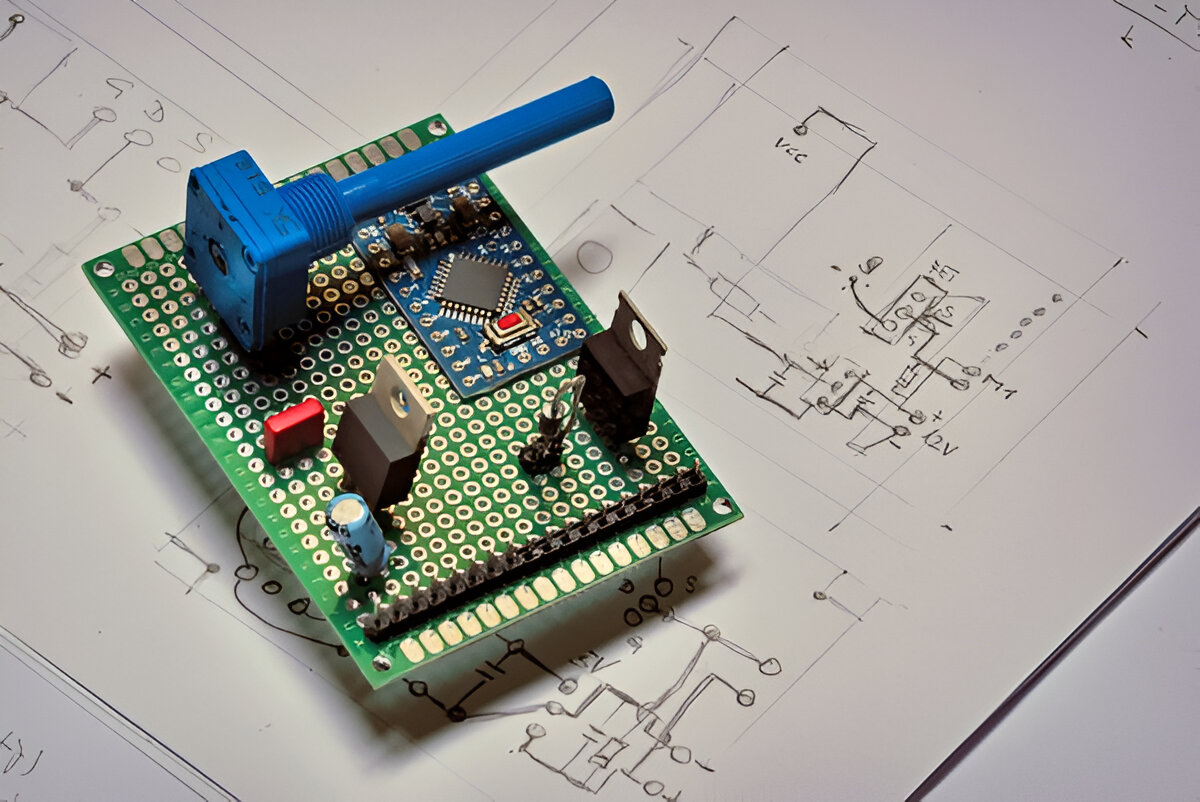

Prototyping and low-volume assembly are essential services for businesses looking to test and refine their designs before mass production. These processes allow companies to produce a small batch of PCBs or electronic assemblies to evaluate functionality, design, and performance. In the prototyping phase, engineers and designers can quickly identify any design flaws or optimize the assembly process before scaling up. This approach is ideal for startups, product development teams, and businesses launching new products, as it reduces time-to-market and lowers production costs. Aear provides robust prototyping and low-volume assembly services, offering fast turnaround times and high-quality production. Whether you need a single prototype or a batch of low-volume assemblies, our experienced team ensures that every piece meets the highest standards of quality and precision, allowing for smoother transitions into mass production.

Aear leverages state-of-the-art equipment and an experienced team to deliver exceptional quality during the prototyping and low-volume assembly stages. With rigorous testing, meticulous quality control, and the use of premium components, we ensure that prototypes and low-volume products are produced with the same reliability and performance as high-volume production runs.

Aear ensures precision and efficiency in prototyping and low-volume assembly, delivering reliable, high-quality results that meet your exact requirements.

Box build assembly refers to the complete assembly of electronic products, integrating printed circuit boards (PCBs) with additional components, enclosures, and packaging into a finished product ready for use. This service typically involves the assembly of the electrical, mechanical, and cosmetic elements of a device, ensuring all components work seamlessly together. Box build assembly is particularly valuable for industries such as consumer electronics, medical devices, and industrial equipment, where the integration of complex parts is critical for performance and safety. Aear specializes in providing comprehensive box build assembly services, ensuring that all parts and assemblies are meticulously integrated, tested, and optimized to deliver high-quality products. Our expertise in handling both electronic and mechanical components, alongside rigorous quality control, guarantees that the final product meets the highest standards of functionality and durability.

Aear’s skilled team works with precision and attention to detail throughout the box build assembly process, using advanced technology and top-tier quality control to ensure that each component is flawlessly integrated, resulting in a reliable and high-performance end product.

Aear offers efficient and precise box build assembly services, ensuring every product meets your specifications and quality standards.