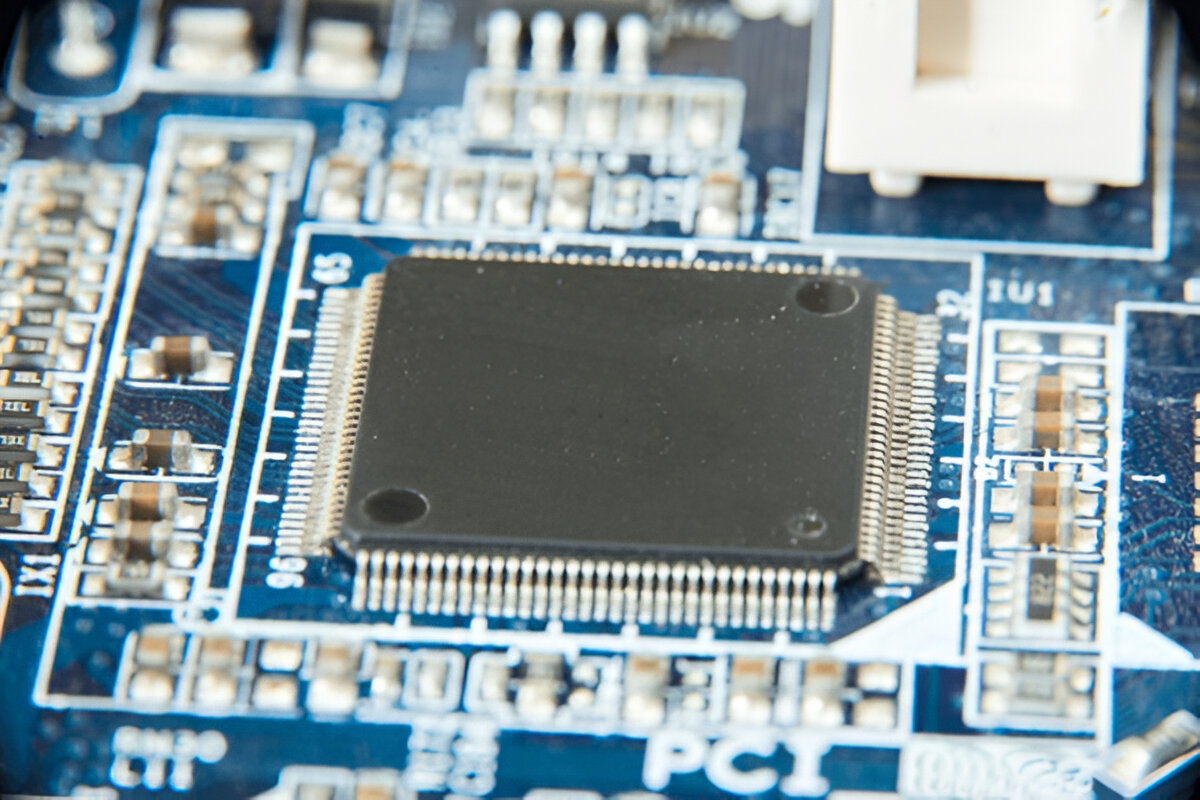

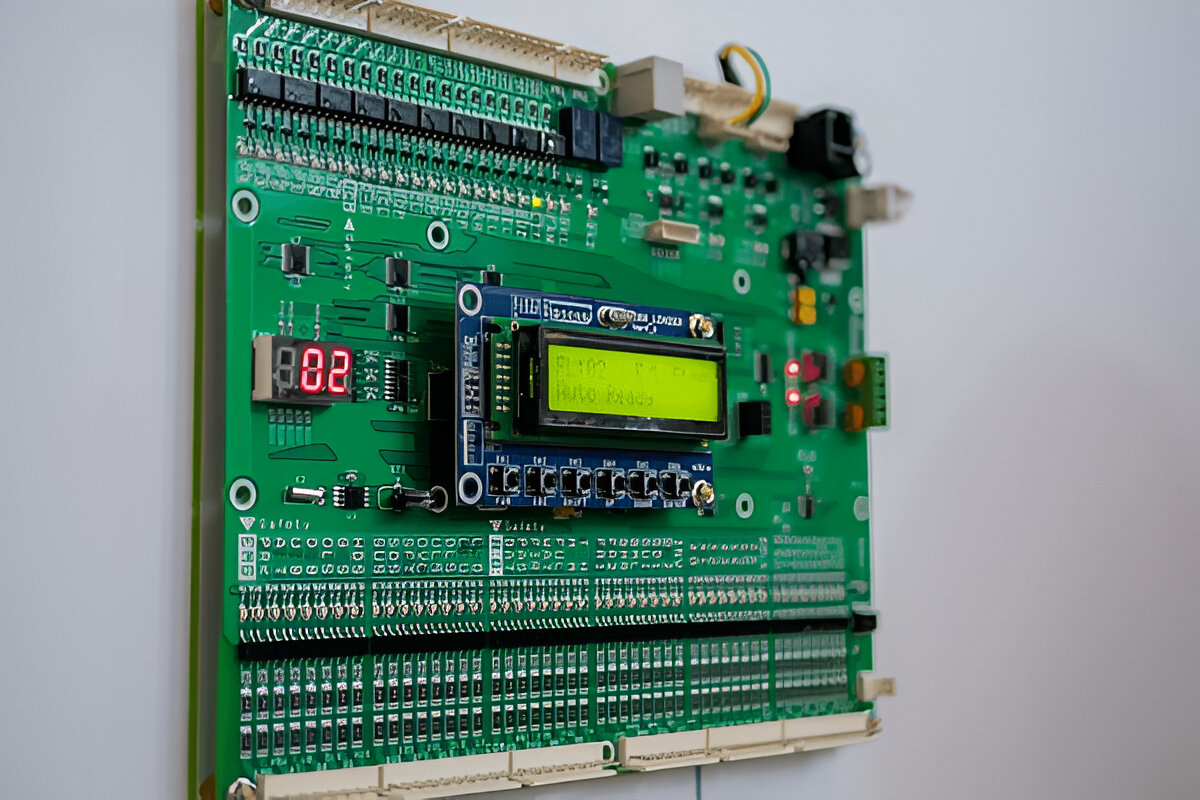

Prototype PCB Fabrication is an essential phase in the electronics development process, allowing engineers and designers to create and test circuit boards before mass production. At Aear, we specialize in turning your innovative designs into functional prototypes, employing advanced techniques and high-precision equipment. Using high-quality materials like FR4, our fabrication process is tailored to meet the specific requirements of each project, ensuring that every prototype accurately reflects your design intentions. From single-layer boards to complex multi-layer configurations, we are dedicated to providing rapid turnaround times, enabling you to test and iterate quickly.

Our commitment to quality in Prototype PCB Fabrication is reflected in our rigorous testing and quality assurance processes. We utilize state-of-the-art equipment to validate each prototype against your specifications, ensuring optimal performance and reliability. Our experienced team works closely with you throughout the fabrication process, leveraging their expertise to resolve any challenges and enhance the design, ensuring that your prototypes are built to the highest standards.

At Aear, we pride ourselves on our efficient handling of orders for Prototype PCB Fabrication. Our streamlined process is designed to ensure timely delivery while maintaining the highest quality standards. Our team collaborates with you to understand your specific requirements, allowing us to provide tailored solutions that meet your project deadlines. With a focus on precision and excellence, Aear is committed to delivering prototypes that not only meet but exceed your expectations, empowering you to move forward confidently with your electronic projects.

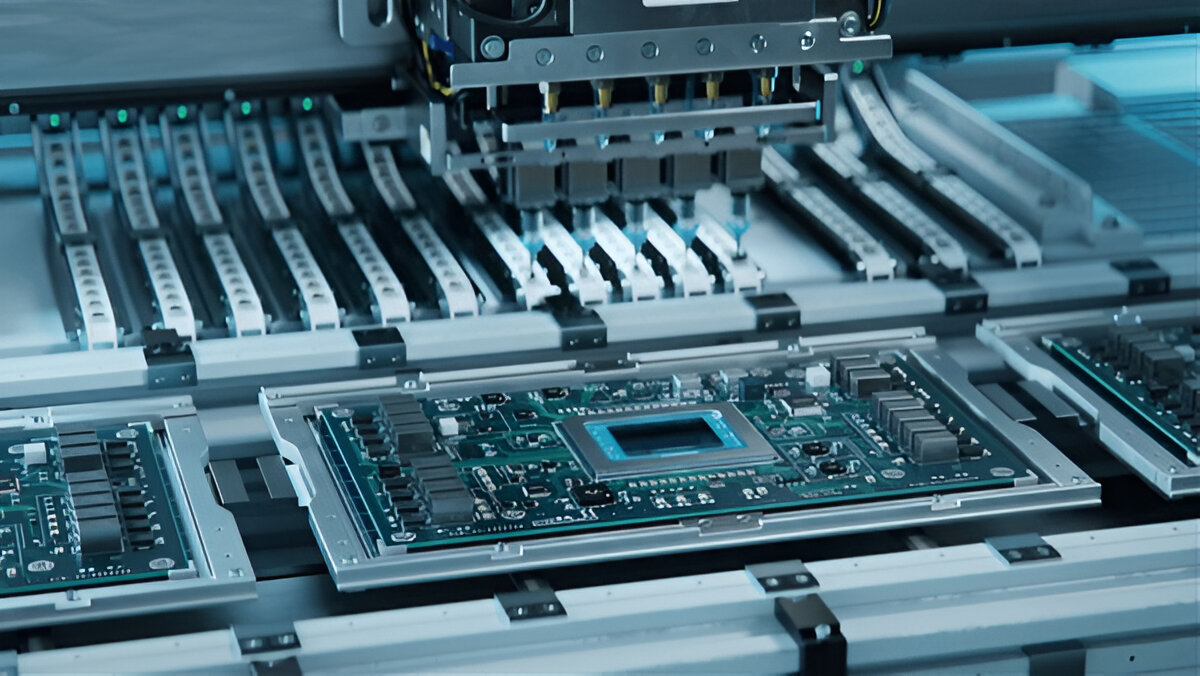

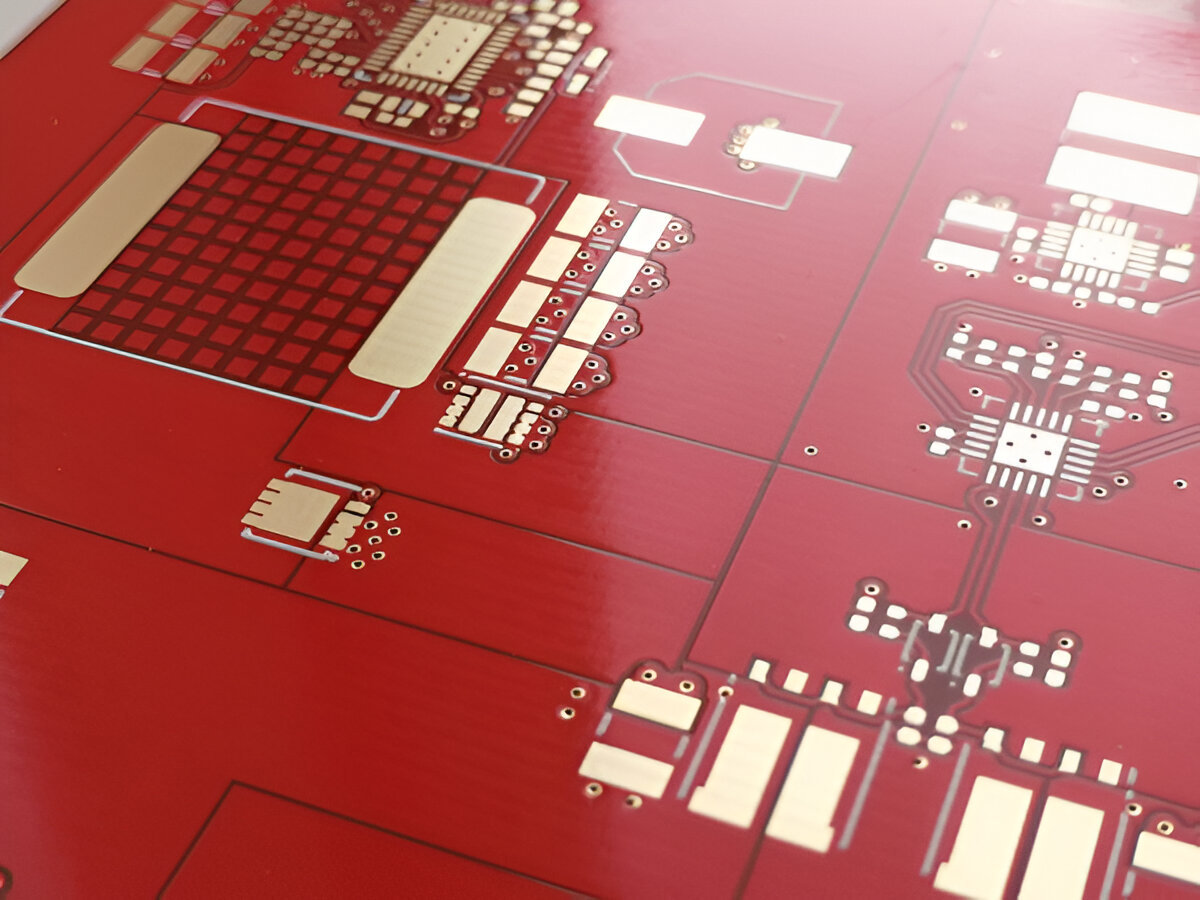

High-Volume PCB Manufacturing is crucial for companies looking to scale their production efficiently without compromising quality. At Aear, we harness advanced manufacturing technologies and streamlined processes to deliver high-quality printed circuit boards at scale. Our production facilities are equipped with state-of-the-art machinery and automated workflows, allowing us to handle large orders with speed and precision. We prioritize every step of the manufacturing process, from materials selection to final assembly, ensuring that our boards meet stringent performance standards. With our expertise, we can support various industries, including telecommunications, automotive, and consumer electronics, by providing reliable and durable PCBs tailored to their needs.

Quality is paramount in our High-Volume PCB Manufacturing process. Aear employs rigorous quality control measures throughout production, including automated inspection systems and testing protocols to ensure every board meets the required specifications. Our team of experts continuously monitors the manufacturing process to identify and resolve potential issues proactively, guaranteeing that our customers receive the best possible product. By combining high-volume capabilities with uncompromising quality, we ensure that your projects are delivered on time and to your exact requirements.

At Aear, we understand the importance of efficient order handling in High-Volume PCB Manufacturing. Our dedicated team works closely with clients to ensure that all specifications are met while maintaining optimal lead times. With our focus on effective communication and collaboration, we are able to quickly adapt to changing project demands. Aear is committed to providing top-tier quality and service throughout the manufacturing process, ensuring that your high-volume orders are completed with precision and delivered as promised, allowing you to meet market demands effectively.

At Aear, we specialize in producing Rigid, Flexible PCB Manufacturing, and Rigid-Flex PCBs, offering innovative solutions tailored to meet the unique needs of various applications. Rigid PCBs provide a solid base for electronic components, ensuring durability and reliability in demanding environments. Flex PCBs, on the other hand, offer the flexibility to fit into compact spaces and complex designs, making them ideal for devices that require bending or folding. Rigid-Flex PCBs combine the advantages of both rigid and flexible circuits, allowing for increased design freedom and reducing the number of interconnects, which enhances reliability and performance. Our experienced engineers leverage cutting-edge design tools and fabrication techniques to produce PCBs that meet high Flexible PCB Solutions for Industrial Use. standards, from concept to final assembly, ensuring that your electronic devices function seamlessly.

Aear is dedicated to delivering the best quality Rigid, Flex, and Rigid-Flex PCBs through stringent quality control measures and advanced manufacturing processes. We utilize state-of-the-art technology, such as automated inspection systems and advanced testing protocols, to guarantee that every board meets the required specifications. Our commitment to excellence extends to sourcing high-quality materials and maintaining a skilled workforce, ensuring that we consistently deliver reliable and durable products to our customers.

At Aear, we take pride in our ability to handle orders efficiently for Rigid, Flex, and Rigid-Flex PCBs. Our dedicated team collaborates closely with clients to understand their project requirements and ensure that every aspect of the manufacturing process is aligned with their specifications. With a focus on effective communication, we can quickly adapt to changes and provide timely updates throughout the production cycle. Aear’s commitment to quality assurance and customer satisfaction means that your PCBs will be produced with the utmost care and precision, ensuring they meet the demands of your applications and are delivered on time.

At Aear, we specialize in the production of Metal Core PCBs (MCPCBs), designed to enhance thermal management and reliability in high-performance applications. MCPCBs incorporate a metal substrate, typically aluminum or copper, which effectively dissipates heat generated by electronic components, making them ideal for LED lighting, power supplies, and automotive applications. Our team uses advanced manufacturing techniques to ensure precise design and fabrication, allowing for the integration of complex circuitry while maintaining exceptional thermal performance. With a focus on innovation and quality, Aear’s Metal Core PCBs provide reliable solutions that meet the demanding needs of modern electronic devices.

Aear’s commitment to quality in Metal Core PCB fabrication stems from our rigorous quality assurance processes and state-of-the-art technology. We employ high-precision machinery and industry-leading practices to ensure each board meets stringent performance and durability standards. By sourcing top-quality materials and utilizing expert engineering, we guarantee that our MCPCBs deliver superior thermal conductivity and mechanical strength, providing customers with the best possible products for their applications.

At Aear, we excel in efficiently managing orders for Metal Core PCBs, ensuring a seamless experience from initial consultation to final delivery. Our dedicated team collaborates closely with clients to understand their specific requirements, allowing us to customize solutions that meet their unique needs. We prioritize effective communication throughout the production process, providing timely updates and adapting to any changes in project specifications. Aear’s commitment to customer satisfaction and quality assurance means that your Metal Core PCBs will be manufactured with precision and care, ensuring they perform optimally in your applications while being delivered on schedule.

At Aear, we specialize in High-Density Interconnect (HDI) fabrication, a cutting-edge technology that enables the creation of compact and complex circuit designs. HDI PCBs are characterized by their fine line widths and spaces, small vias, and advanced layering techniques, allowing for increased functionality in a smaller footprint. Our manufacturing process utilizes advanced laser drilling and microvia technologies, enabling us to create intricate designs that support high-speed and high-frequency applications. This innovative approach is ideal for various industries, including telecommunications, consumer electronics, and automotive, where space and performance are paramount. With Aear, you can trust that your HDI PCBs are produced with precision and reliability, ensuring they meet the demands of modern electronic applications.

Aear’s commitment to producing the highest quality HDI PCBs stems from our adherence to industry standards and rigorous quality control measures. Our experienced team employs state-of-the-art machinery and processes to ensure each PCB meets exacting specifications. We utilize high-quality materials and advanced manufacturing techniques, allowing us to deliver reliable products that excel in performance and durability.

At Aear, we prioritize customer satisfaction and quality in handling HDI fabrication orders. Our dedicated team works closely with clients to understand their unique project requirements, ensuring tailored solutions that fit their needs. We maintain transparent communication throughout the production process, providing timely updates and accommodating changes to specifications as necessary. Our commitment to excellence ensures that your HDI PCBs are manufactured with precision, delivered on time, and ready to perform optimally in your applications. Trust Aear for your HDI fabrication needs, and experience unparalleled service and quality.

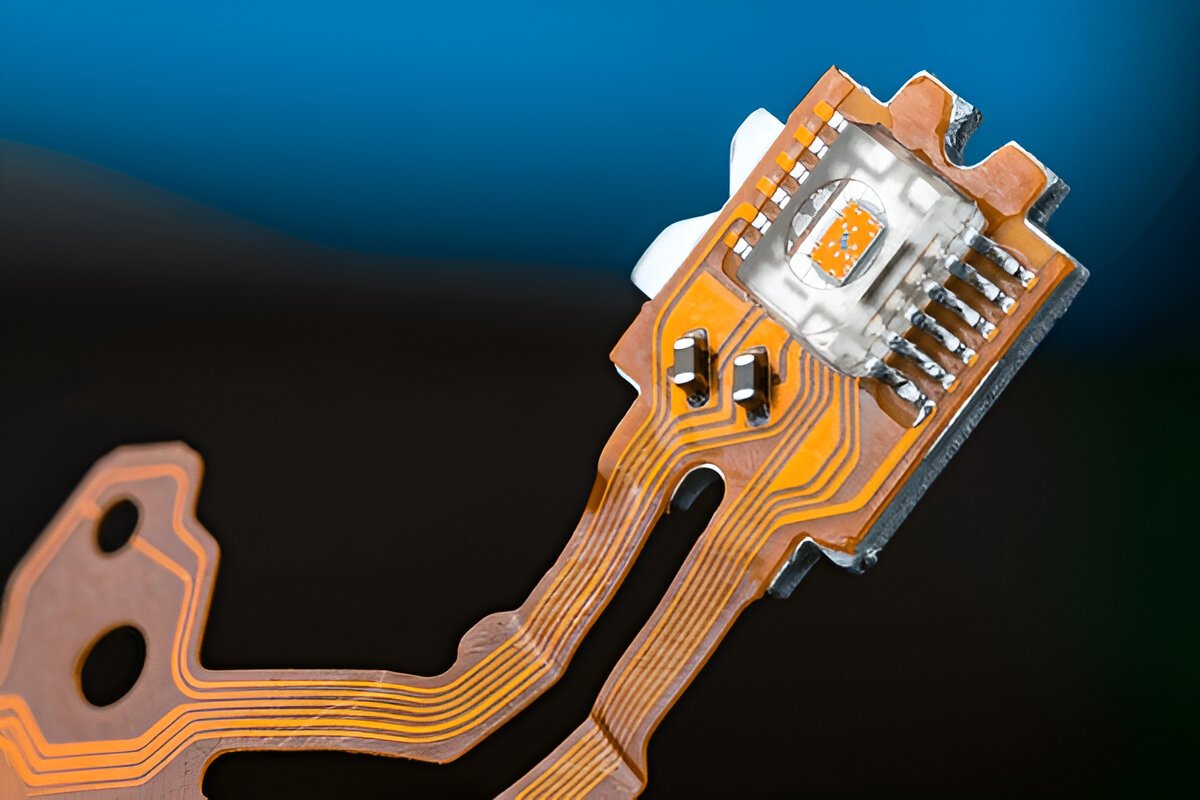

Aear specializes in the fabrication of flexible and stretchable printed circuit boards (PCBs), designed to meet the demands of modern electronic applications that require adaptability and resilience. Our flexible PCBs utilize thin substrates that allow for bending and twisting without compromising performance, making them ideal for use in wearables, medical devices, and advanced consumer electronics. Stretchable PCBs take this innovation a step further, incorporating materials that can endure mechanical stress and strain, enabling the development of devices that conform to various shapes and surfaces. Our fabrication process combines advanced material science with precision engineering to create circuits that maintain electrical performance while accommodating dynamic movement.

At Aear, we pride ourselves on delivering the best quality flexible and stretchable PCBs by leveraging state-of-the-art technology and rigorous testing protocols. Our skilled team ensures that every board is manufactured using high-quality materials, minimizing defects and maximizing durability. By adhering to strict industry standards and utilizing innovative fabrication techniques, we create reliable products that exceed customer expectations.

At Aear, we understand the importance of timely and accurate handling of flexible and stretchable PCB orders. Our team is dedicated to providing exceptional service and ensuring that all project specifications are met. We maintain open lines of communication with our clients, offering regular updates throughout the fabrication process. Our agile manufacturing capabilities allow us to adapt to changes quickly, ensuring that you receive high-quality PCBs that meet your precise requirements. Trust Aear for your flexible and stretchable PCB fabrication needs, and experience the difference that quality and commitment can make.

Aear excels in providing custom PCB thickness and material selection services, ensuring that each project meets specific performance and application requirements. Our expert team collaborates closely with clients to determine the optimal thickness and materials for their unique designs. We utilize a variety of substrates, including FR-4, polyimide, and Rogers materials, which allow for diverse thermal and electrical properties. The thickness of PCBs can significantly impact their performance, influencing aspects such as signal integrity, thermal management, and mechanical stability. By considering factors like operating environment and intended application, we can create tailored solutions that enhance device functionality and reliability.

To guarantee the highest quality, Aear employs rigorous material selection processes, evaluating each option based on durability, thermal conductivity, and electrical performance. We ensure that the materials chosen not only meet industry standards but also align with the specific needs of our clients. Our commitment to using superior materials and maintaining quality control throughout the fabrication process results in PCBs that are reliable and efficient, providing exceptional performance in their intended applications.

At Aear, we prioritize effective order management to deliver custom PCBs that meet your exact specifications. Our dedicated team ensures a seamless process from consultation to fabrication, providing timely updates and addressing any queries you may have. By utilizing advanced manufacturing techniques and maintaining strong communication throughout the project, we guarantee that our custom PCBs will meet the highest standards of quality and performance. Trust Aear to fulfill your custom PCB thickness and material selection requirements, and experience unparalleled service and expertise in every aspect of your project.

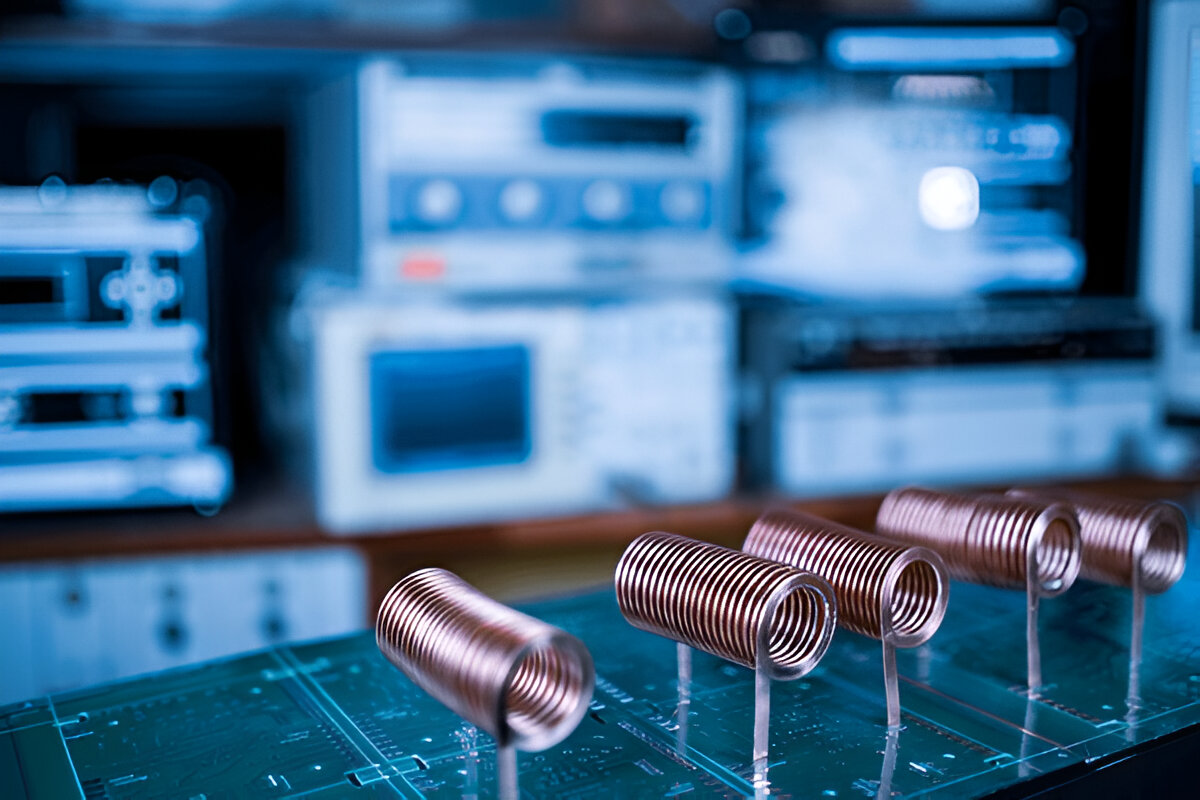

At Aear, we specialize in the design and fabrication of controlled impedance PCBs, which are essential for high-frequency applications. These PCBs are meticulously engineered to maintain a specific impedance, ensuring signal integrity and performance in demanding environments. Our design team utilizes advanced simulation tools to calculate the required trace width, spacing, and substrate material, allowing us to achieve the desired impedance for your application. By focusing on factors such as dielectric constant and thickness, we create PCBs that minimize signal loss and reflection, optimizing the performance of high-speed electronic devices.

To ensure the highest quality in our controlled impedance PCBs, Aear employs stringent testing protocols throughout the manufacturing process. We utilize specialized equipment to measure impedance and verify compliance with industry standards, guaranteeing that every PCB meets the specified performance criteria. Our commitment to precision and quality control allows us to deliver reliable, high-performance solutions that meet the complex demands of modern electronics.

At Aear, we excel in managing your orders for controlled impedance PCBs with efficiency and precision. Our dedicated team provides personalized service throughout the entire process, from initial design consultation to final fabrication. We prioritize clear communication, ensuring that you are kept informed at every stage of production. By leveraging state-of-the-art technology and best practices in PCB manufacturing, we deliver high-quality products that exceed your expectations. Trust Aear to meet your controlled impedance PCB requirements, and experience exceptional service and performance in every project.

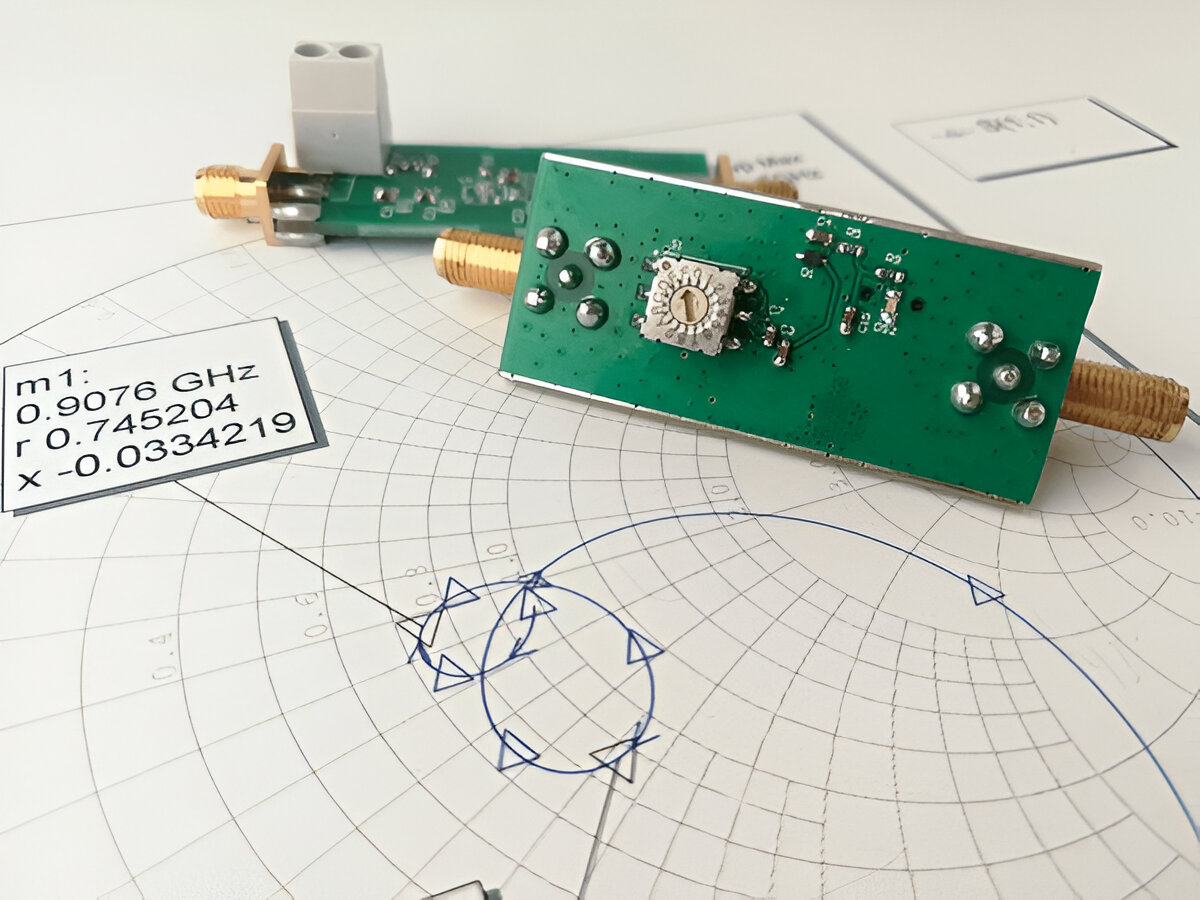

At Aear, we specialize in high-frequency and RF PCB fabrication, crucial for ensuring optimal performance in telecommunications, radar systems, and various wireless applications. Our process begins with precise design and layout, utilizing advanced simulation tools to model electromagnetic behavior and ensure signal integrity. We understand the unique challenges associated with RF circuits, such as minimizing signal loss and managing interference. By carefully selecting appropriate materials, trace geometries, and layer stack-ups, we create PCBs that excel in high-frequency environments, meeting the rigorous demands of modern electronic applications.

Aear guarantees the highest quality in high-frequency and RF PCB fabrication by implementing stringent testing and quality control measures throughout the manufacturing process. Our team employs advanced equipment to test parameters such as insertion loss, return loss, and crosstalk, ensuring each board meets industry standards and client specifications. With our expertise and commitment to excellence, we provide reliable and high-performance PCBs tailored to your specific needs.

At Aear, we pride ourselves on managing your high-frequency and RF PCB fabrication orders with efficiency and precision. Our dedicated team is committed to providing exceptional customer service, guiding you through every step of the process—from initial consultations to final delivery. We emphasize transparent communication, ensuring you are informed and involved at all stages of production. By leveraging cutting-edge technology and industry best practices, we deliver high-quality products that not only meet but exceed your expectations. Trust Aear for your high-frequency and RF PCB fabrication needs and experience unparalleled service and performance.

Aear is at the forefront of high-Tg and halogen-free PCB fabrication, offering products designed for superior thermal performance and environmental sustainability. High-Tg (glass transition temperature) materials are essential in applications exposed to high temperatures, ensuring durability and reliability. Our fabrication process involves meticulous material selection and advanced manufacturing techniques to produce PCBs that can withstand demanding conditions while maintaining structural integrity. We prioritize environmentally friendly practices, utilizing halogen-free laminates that reduce harmful emissions during manufacturing and disposal. This commitment not only enhances product longevity but also aligns with global standards for eco-friendliness, making our PCBs a smart choice for conscientious manufacturers.

To achieve the best quality in high-Tg and halogen-free PCBs, Aear employs rigorous quality control processes at every stage of production. Our experienced engineers and technicians conduct thorough testing to ensure that all boards meet or exceed industry standards for thermal performance and environmental safety. We continuously invest in the latest technology and processes to maintain high quality and reliability, ensuring our customers receive only the best products.

At Aear, we excel in managing your high-Tg and halogen-free PCB fabrication orders with unparalleled efficiency and attention to detail. Our dedicated team collaborates closely with you throughout the entire process, from initial design consultations to final production and delivery. We believe in maintaining transparent communication, ensuring you are informed and engaged every step of the way. By leveraging our expertise and state-of-the-art technology, we deliver high-quality, environmentally responsible PCBs tailored to your specific needs. Choose Aear for your high-Tg and halogen-free PCB requirements, and experience a seamless and reliable partnership that prioritizes your satisfaction and success.