World-Class PCB Assembly Services

From prototype to production – fast, reliable, and precise PCBA solutions.

Explore ServicesOur Assembly Services

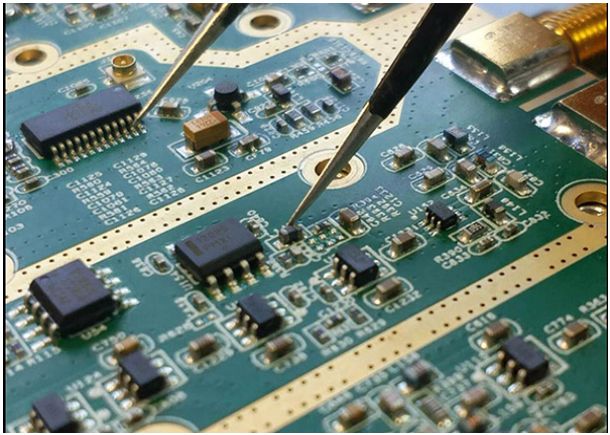

Prototype PCB Assembly

We provide quick and reliable prototype PCB assembly services designed to help you test, validate, and refine your designs before moving into mass production. With advanced tools and skilled engineers, our prototyping ensures accuracy, minimizes design errors, and accelerates time-to-market for your innovative electronic products.

Low Volume PCB Assembly

Our low volume PCB assembly service is ideal for startups, R&D teams, and pilot projects. We provide flexible production runs with high precision, ensuring every unit meets industry standards. This helps you scale gradually, maintain quality, and test market-ready products before committing to full-scale manufacturing processes.

High Volume PCB Assembly

We specialize in high volume PCB assembly using fully automated production lines that ensure consistency, speed, and cost efficiency. Designed for mass production, our process minimizes defects, maintains international standards, and supports industries requiring large-scale output, such as automotive, industrial, and consumer electronics manufacturing sectors worldwide.

Turnkey PCB Assembly

Our turnkey PCB assembly solution covers everything from component sourcing to assembly, testing, and delivery. This all-in-one approach saves time, reduces costs, and eliminates the hassle of dealing with multiple vendors. With complete transparency and quality assurance, we ensure your projects are delivered efficiently and on schedule.

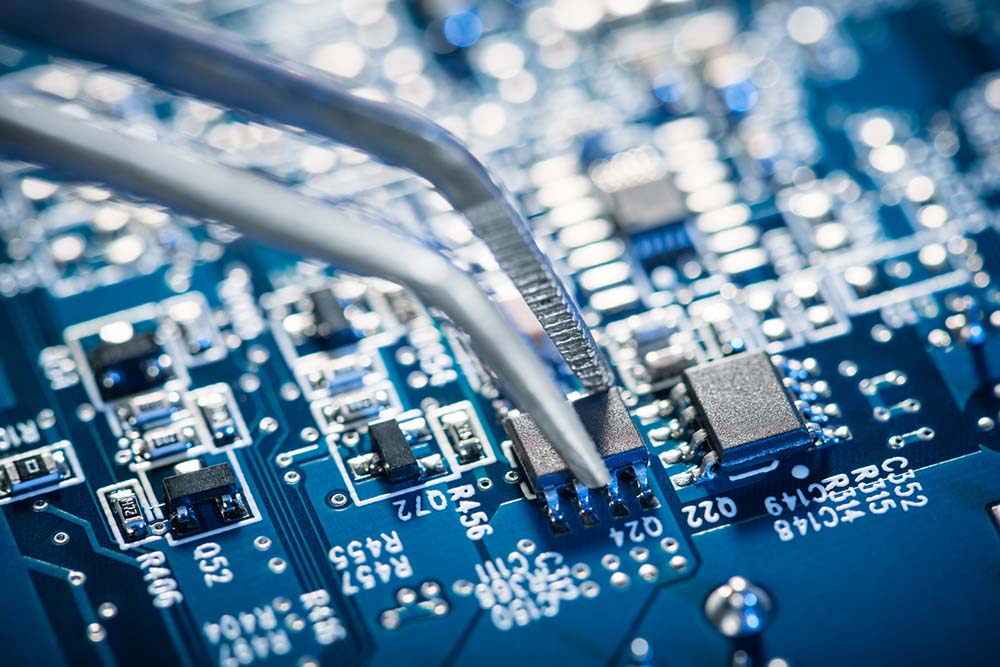

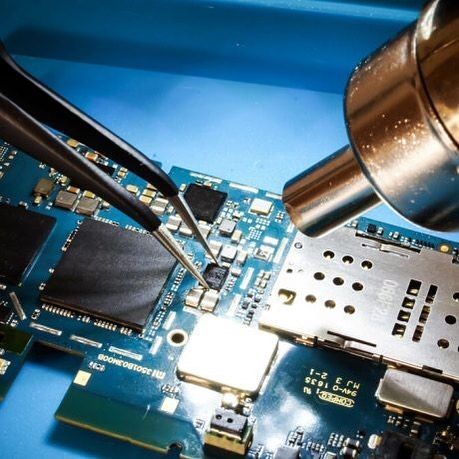

SMT Assembly

Our SMT (Surface Mount Technology) assembly service delivers precise placement of components on compact PCBs, meeting the demands of modern electronics. With high-speed machines and expert technicians, we ensure flawless soldering, reduced costs, and improved performance for consumer electronics, communication devices, and industrial-grade equipment worldwide.

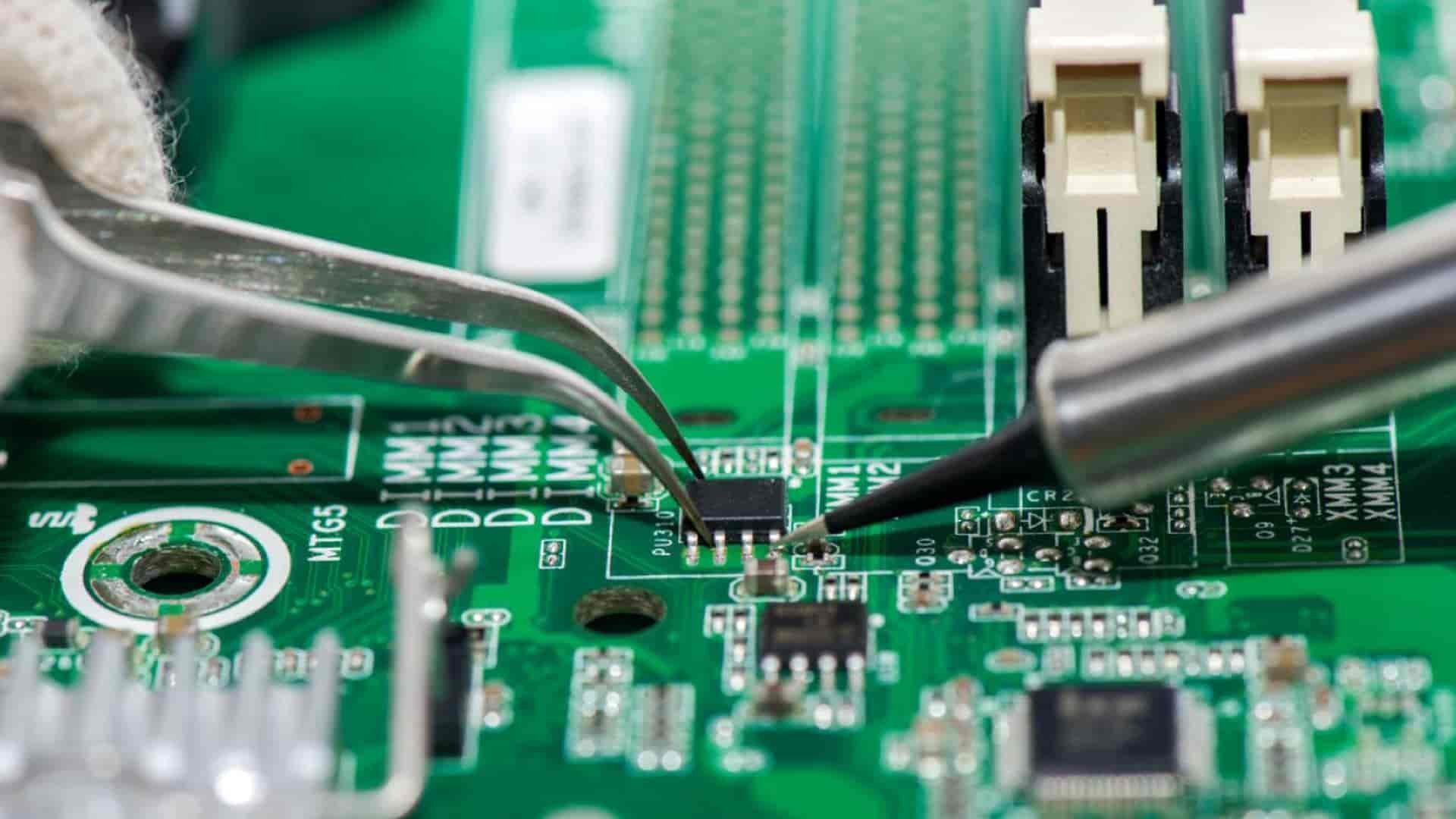

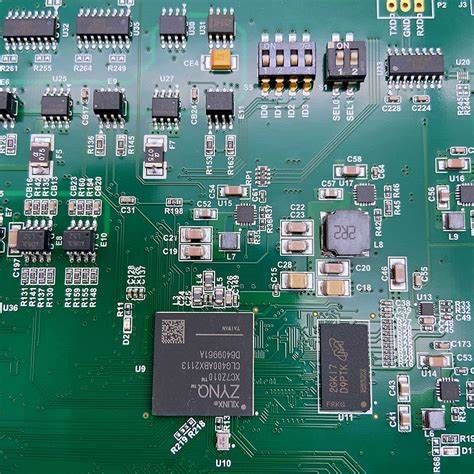

BGA Assembly

We provide specialized BGA (Ball Grid Array) assembly services to support advanced, high-density circuit designs. Using X-ray inspection and precise reflow soldering techniques, we guarantee reliable connections and durability. This is essential for applications in computing, telecommunications, and devices requiring complex integrated circuit packaging solutions worldwide.

Cable Assembly

Our cable assembly service offers custom-built cable and wire harness solutions tailored to your project needs. We ensure durability, accurate connectivity, and safety compliance. From prototypes to large-scale production, our assemblies are used in automotive, industrial machinery, medical devices, and consumer electronics applications globally.

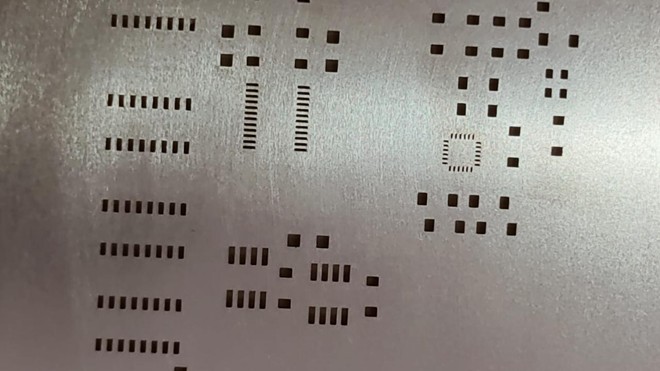

Laser Stencil

Our laser stencil services provide precision-cut stencils for accurate solder paste application during SMT processes. With high-quality stainless steel and advanced laser cutting technology, we ensure clean apertures, perfect alignment, and reduced defects. This guarantees smooth assembly and reliable performance in every production cycle.

10M+

Components Placed

ISO 9001

Certified Facility

24 hrs

Prototype Lead Time

500+

Global Clients

Our Assembly Services

SMT Assembly

High-speed Surface Mount Technology for precision assembly.

Through-Hole Assembly

Reliable soldering for components requiring durability.

Mixed Technology

Combining SMT & THT to match your design requirements.

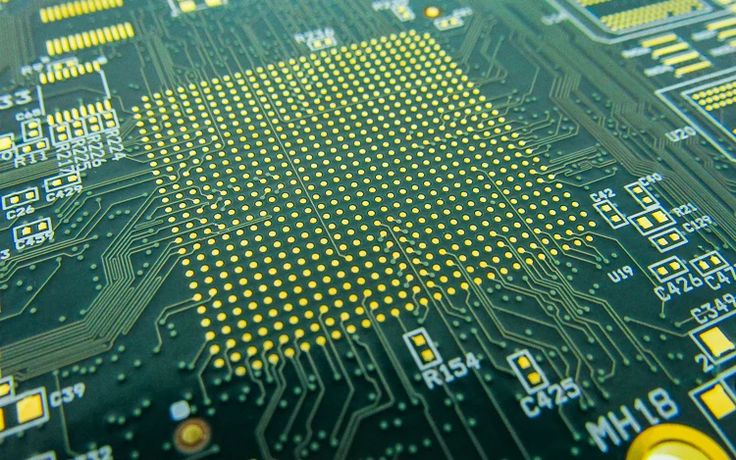

BGA & Fine Pitch

Advanced assembly for complex IC packages.

Turnkey PCBA

Complete solution including parts sourcing and testing.

Capabilities

Component Size

Down to 01005

Layers

Up to 32 Layers

Lead Time

1–7 Days

Testing

ICT, AOI, X-ray

Our Process

Procurement

Assembly

Testing

Delivery

Industries We Serve

Medical

Automotive

Consumer Electronics

Industrial

Gallery