Premium PCB Layout & Design for Prototypes to Mass‑Production

We turn schematics into manufacturable boards with controlled impedance, clean return paths, stack‑up planning, and assembly‑ready outputs (Gerbers, ODB++, pick‑and‑place, BOM).

Why Choose Us

Engineering‑first approach with strong DFM/DFT focus and EMI/EMC best practices.

High‑Speed Expertise

DDR, PCIe, MIPI, USB 3.x with skew/length matching and impedance control.

RF / Microwave

Stack‑ups for low‑loss materials, controlled transitions, and shielding strategy.

Manufacturable

IPC‑7351 footprints, Fab notes, panelization, and assembly‑ready outputs.

Quality & Review

ERC/DRC, checklist‑based peer reviews, and free DFM report with every job.

PCB Design Services

End‑to‑end from schematic capture to assembly files.

PCB Layout

2–20+ layers, analog, digital, mixed‑signal with proper PDN & return paths.

- Length matching & diff‑pair tuning

- Impedance controlled routing

- Thermal relief & copper balance

High‑Speed Design

DDRx, PCIe, Ethernet, HDMI, MIPI with constraints and timing closure.

- Skew budgeting & xTalk control

- Via strategy & back‑drilling

- Stack‑up co‑design with fab

RF & Microwave

50/75Ω lines, microstrip/stripline, controlled transitions & grounding.

- EMI/EMC best practices

- Shielding & keep‑out strategy

- Connector launch tuning

Flex / Rigid‑Flex

Bend radius rules, stiffener planning, and dynamic‑flex reliability.

- Coverlay openings & teardrops

- Hatched copper & strain relief

- ZIF/connector footprints

DFM/DFT Review

Fabrication constraints, assembly checks, test‑point planning & panelization.

- Solderability & tombstoning checks

- Pick‑and‑place verification

- AOI/ICT readiness

Deliverables

Complete outputs for fab & assembly.

- Gerber/ODB++, drill, fab notes

- BOM with MPN & alternates

- Pick‑and‑place, centroid, PDFs

Design Capabilities

We engineer for signal integrity, power integrity, and reliability.

- Up to 24 layers, blind/buried vias, via‑in‑pad, microvias

- Impedance control & stack‑up co‑design with fabricator

- PDN design with stitching vias & decoupling strategy

- Thermal analysis & copper balancing

- Compliance oriented (IPC‑2221/7351, RoHS/REACH)

- Libraries with 3D models & courtyard checks

How It Works

Transparent steps from requirement to release.

1. Requirement & NDA

Share schematics, constraints, preferred stack‑up, part libraries, and timelines. We can sign an NDA.

2. Feasibility & Quote

We assess complexity, propose milestones, and share a fixed quote or hourly estimate.

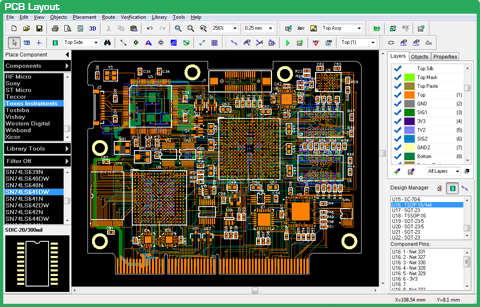

3. Layout Execution

Constraint‑driven routing with periodic design reviews and build‑ready checks.

4. Release & Support

Deliverables: Gerber/ODB++, drill, fab notes, panel, BOM, CPL. Free support until first proto spin.

What We Need for Quoting

- Schematics (PDF/Source) and block diagram

- Target board size, layers, interfaces, key ICs

- Speed classes (e.g., DDR3/4, PCIe Gen, USB 3.x)

- Specials: impedance, RF, flex, via‑in‑pad, microvia

- Any preferred standards, fab/assembly house

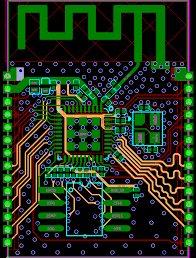

Recent Work

Representative renders and board photos (placeholders).

FAQ

Answers to common questions.

Ready to start your PCB design?

Share your schematics and constraints—we’ll revert with a plan and quote.

Start Now