PCB Stack-Up Design Services

Optimize your multilayer PCB with professional stack-up planning for signal integrity and reliability.

Request a Fast QuoteWhat is PCB Stack-Up?

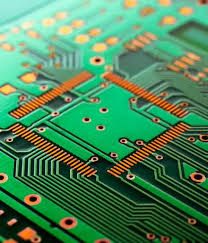

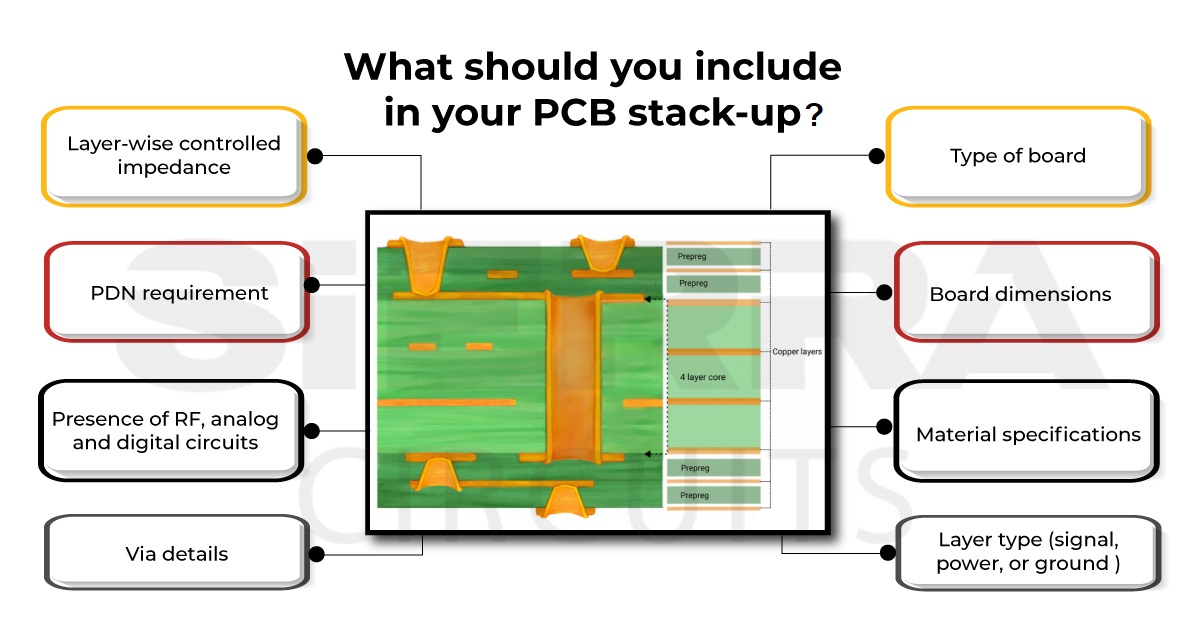

A PCB stack-up defines the arrangement of copper and insulating layers in a printed circuit board. A good stack-up reduces electromagnetic interference, enhances signal quality, and ensures manufacturability. We offer optimized stack-up solutions for simple 2-layer to complex 16+ layer PCBs.

Types of Stack-Ups

Single Layer

Basic PCB with one copper layer.

Double Layer

Two copper layers for moderate complexity designs.

4-Layer

Signal, ground, and power planes for stable designs.

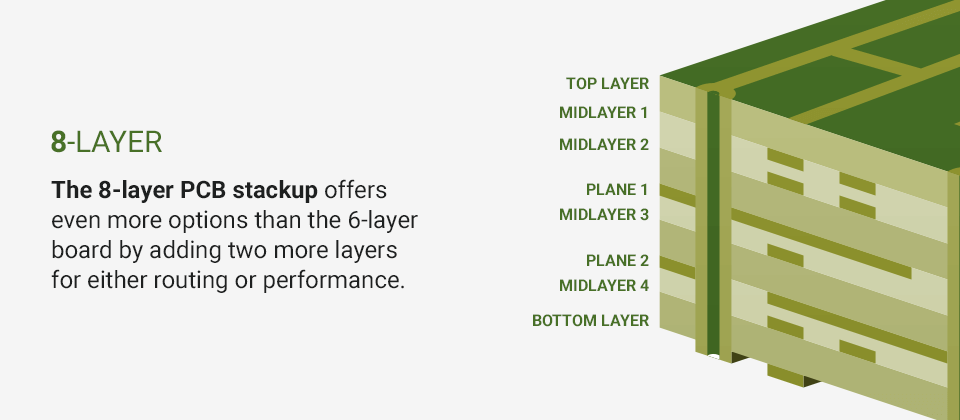

6-Layer & 8-Layer

For high-speed designs with multiple reference planes.

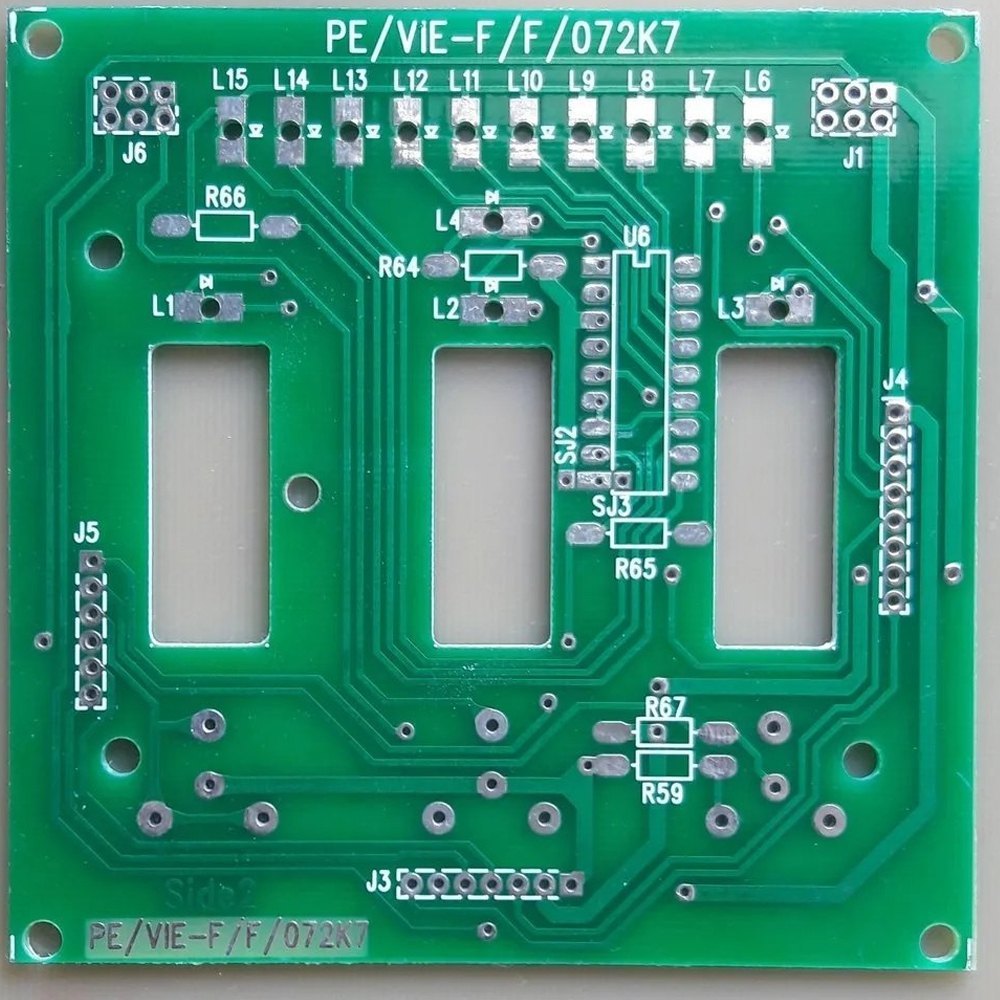

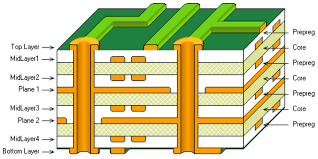

Typical Layer Stack Example (4-Layer)

| Layer | Description |

|---|---|

| Top Layer | Copper + Soldermask + Silkscreen |

| Prepreg | Insulation layer |

| Inner Layer 1 | Ground Plane |

| Core | Dielectric material |

| Inner Layer 2 | Power Plane |

| Prepreg | Insulation layer |

| Bottom Layer | Copper + Soldermask + Silkscreen |

Applications & Industries

Telecom & Networking

Automotive Electronics

Medical Devices

Aerospace & Defense

Advantages of Proper Stack-Up

- Improved signal integrity and reduced crosstalk

- Controlled impedance for high-speed signals

- Better EMI/EMC performance

- Efficient thermal management

- Optimized manufacturability

Our Stack-Up Process

Requirement Analysis

Layer Planning

Simulation & Validation

Final Documentation

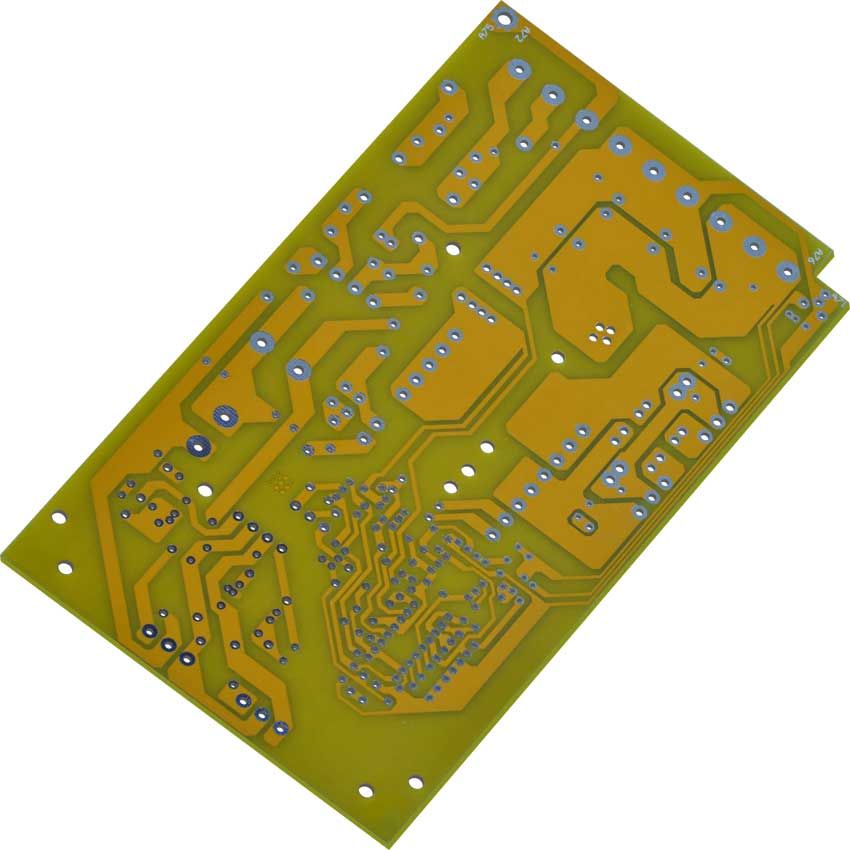

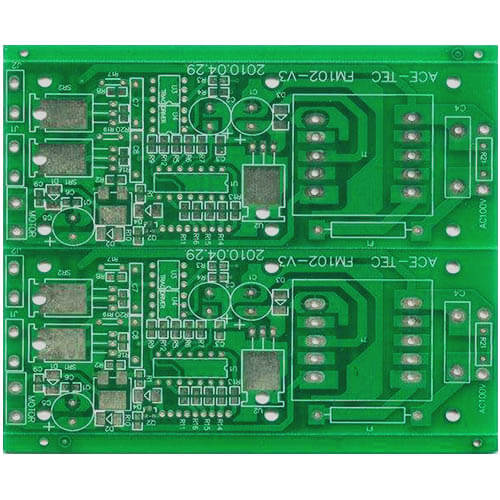

Sample Stack-Ups

Frequently Asked Questions

It improves signal quality, reduces EMI, and ensures reliable performance.

We support from 2 layers up to 16+ layers including HDI and RF boards.